A120 STEEL RAIL DIN 536 – EUROPEAN STANDARD, HEAVY-DUTY LOAD CAPACITY

1. What is an Steel Rail?

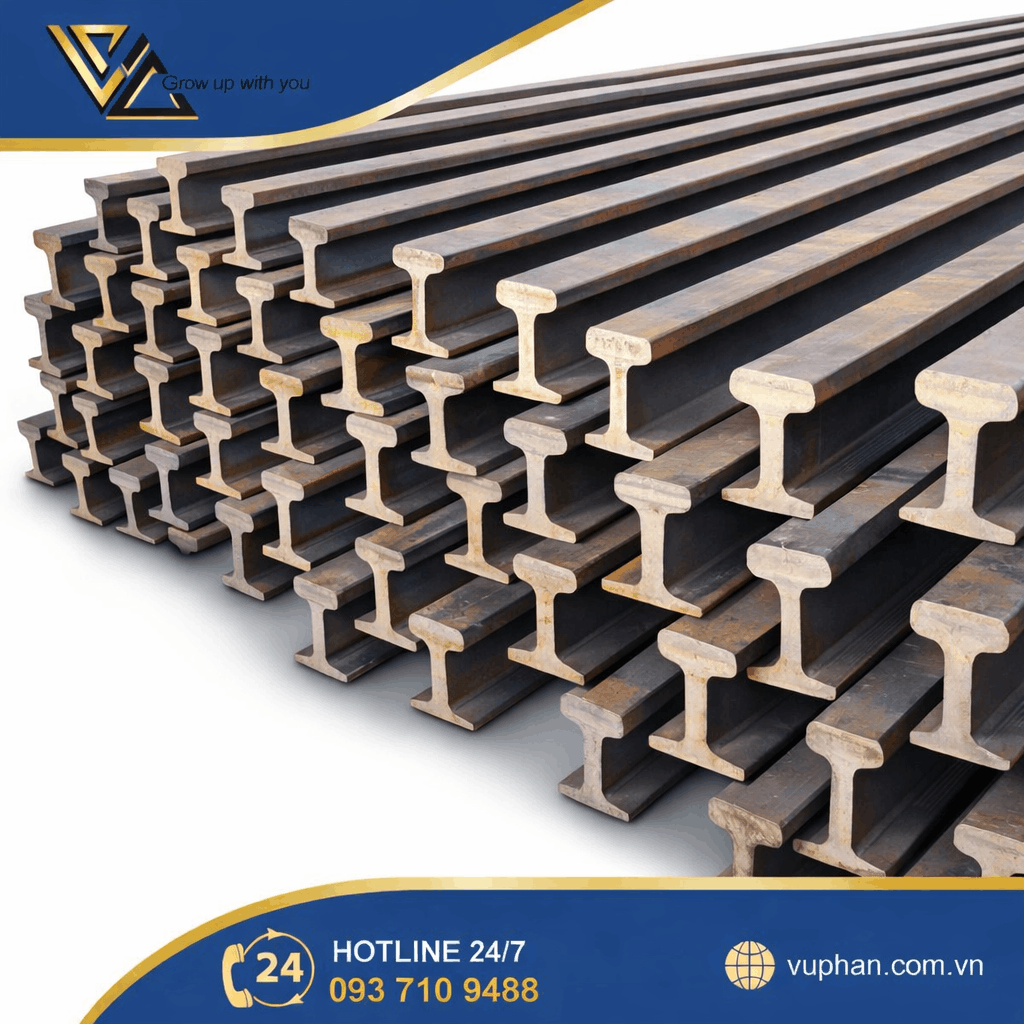

Steel Rail A 120 is a heavy-duty industrial steel rail used as the running track for overhead cranes, gantry cranes, hoists, and high-capacity lifting systems in steel plants, ports, and heavy industrial zones.

Steel rail A 120 is manufactured in accordance with the European standard DIN 536, ensuring:

High geometric accuracy,

High load-bearing capacity, and

Long-term operational stability under harsh working conditions.

With a solid steel cross-section, A120 steel rail distributes loads evenly to the supporting structure, reduces crane wheel wear, and ensures safe, stable, and durable operation of the crane runway system over time.

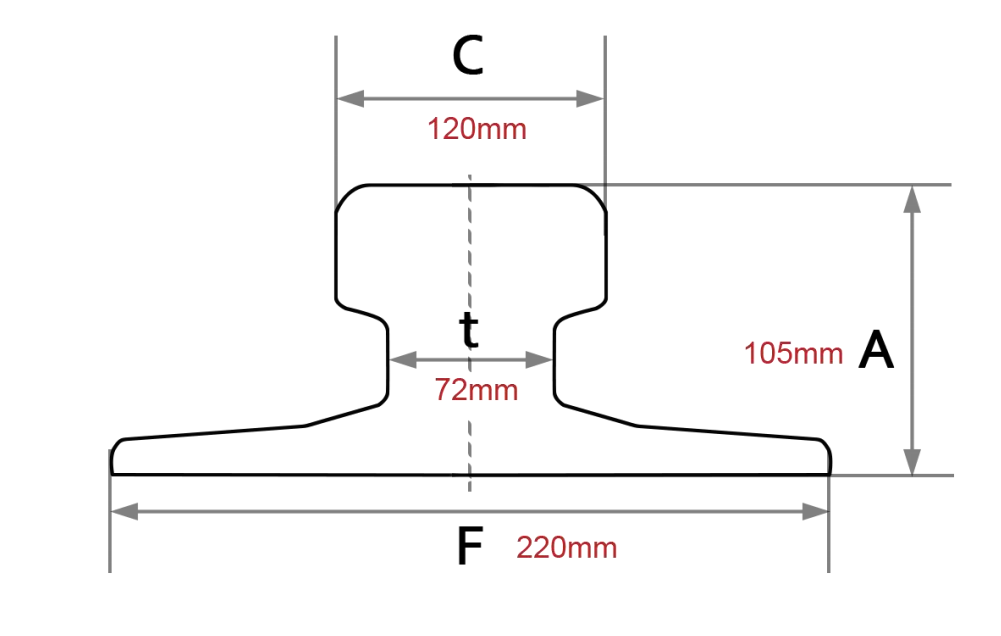

1.1 Structure of A120 Steel Rail DIN 536

A120 steel rail consists of three main structural components:

Rail Head: The top surface in direct contact with crane wheels, designed to withstand heavy loads and continuous wear during operation.

Web: The vertical section connecting the rail head and rail base, responsible for load transmission and overall structural stability.

Rail Foot (Base): The bottom section in contact with steel beams or concrete foundations, where rubber pads and steel rail fastening systems are installed.

The A120 steel rail profile is optimized according to DIN standards to ensure high load capacity, minimize deformation, and extend service life.

1.2 Dimensions and Technical Specifications of A120 Steel Rail DIN 536

Typical technical specifications of A120 steel rail DIN 536 include:

Rail height: approximately 105 mm

Base width: approximately 220 mm

Standard length: 10 m – 12 m

Steel grade: ≥ 880 N/mm² (R880)

Surface condition: anti-rust oil coated

These specifications fully meet the technical requirements for heavy-duty steel rails used in industrial crane runway systems in accordance with European standards.

1.3 A120 Steel Rail Manufacturing Standard – DIN 536 (Europe)

A120 steel rail is manufactured in compliance with DIN 536, a European standard specifically developed for steel rails used in crane and heavy industrial applications.

DIN 536 strictly defines:

Steel rail profile geometry and dimensional tolerances

Steel chemical composition and mechanical properties

Load-bearing capacity and fatigue strength

Delivery conditions and surface treatment

Using DIN 536 compliant A120 steel rail ensures operational safety, reduced wear, and extended service life of the entire crane runway system.

2. TYPES OF STEEL RAILS ACCORDING TO DIN 536 STANDARD

| Rail Type | Rail Height A (mm) |

Base Width B (mm) |

Head Width C (mm) | Web Thickness (mm) | Weight (kg/m) |

|---|---|---|---|---|---|

| Steel Rail A45 | 55 | 125 | 45 | 24 | 22.10 |

| Steel Rail A55 | 65 | 150 | 55 | 31 | 31.80 |

| Steel Rail A65 | 75 | 175 | 65 | 38 | 43.10 |

| Steel Rail A75 | 85 | 200 | 75 | 45 | 56.20 |

| Steel Rail A100 | 95 | 200 | 100 | 60 | 74.30 |

| Steel Rail A120 | 105 | 220 | 120 | 72 | 100.00 |

| Steel Rail A150 | 150 | 220 | 150 | 80 | 150.30 |

3. MANUFACTURERS OF DIN 536 STEEL RAILS

DIN 536 steel rails are produced by reputable steel mills and OEM manufacturers that meet strict technical requirements for industrial crane runway systems, including:

Steel rail ArcelorMittal – A global steel leader supplying high-quality DIN 536 steel rails

Steel rail Voestalpine – A premium steel manufacturer known for high-precision, heavy-duty steel rails

Steel rail British Steel – Supplier of European-standard steel rails for crane and industrial rail applications

Steel rail Gantrail – A specialized provider of steel rail systems and fastening solutions for heavy industry

Steel rail Baosteel – A major steel producer offering DIN 536 steel rails with a wide size range and competitive pricing

Steel Rail Wuhan Steel – Supplier of steel rails for large-scale industrial and infrastructure projects

DIN 536 compliant OEM manufacturers – Custom-produced steel rails widely used in steel plants, cement factories, warehouses, and industrial zones

Selecting the correct steel rail standard and origin helps reduce crane wheel wear, extend steel rail service life, and ensure stable long-term crane operation.

4. KEY CRITERIA WHEN SELECTING A120 STEEL RAIL

DIN 536 Compliance

Ensure the steel rail is manufactured strictly in accordance with DIN 536 to meet geometric and load-bearing requirements.

Steel Grade & Working Load

Select appropriate steel grade (R900 / R1100) based on crane capacity, operating frequency, and actual working conditions.

Geometric Tolerances

Verify rail height, head width, straightness, and parallelism to minimize vibration and crane wheel wear.

Rail Length & Joint Design

Determine rail length, joint configuration, and expansion gaps to ensure accurate installation and long-term stability.

Complete Installation Accessories

Rubber pads, steel rail clips, and anchor bolts must be selected as a complete system to secure the rail and distribute loads evenly.

Actual Working Environment

Evaluate conditions in steel plants, heavy industrial zones, or ports to select the most suitable steel rail solution.

English

English

Đánh giá

Chưa có đánh giá nào.