What is an indirect inverter? The inverter is one of the devices that is said to support well, bring stability and save electricity to the motors. On the market today, there are many devices that support power transmission to help you choose the right inverter. This article will bring useful information about inverters.

1.What is an indirect inverter?

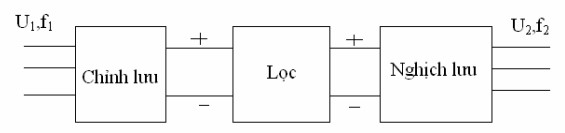

Indirect inverter is a device that operates on the principle of converting input power and grid frequencies to electrical power to match the required frequency for equipment load.

The AC mains power is converted into DC power through the rectifier on the DC busbar. After that, this DC power will be converted into AC power for the load through the inverter.

2.Structure of indirect inverters

To be able to change the frequency, it is necessary to go through an intermediate step of an indirect inverter. The function of the blocks is as follows:

2.1.Rectifier

The function of rectifier is to convert AC voltage into DC voltage. Rectification can also be non-adjustable or adjustable.

Most of today’s rectifiers are unregulated, because wide-range d.c. voltage regulation causes an increase in filter size and a decrease in converter efficiency.

In short, the function of power and frequency converters is performed by the inverter through the control law.

In large power converters, people often use semi-controlled rectifiers with the function of protecting the entire system when overloaded.

Depending on the required inverter stage, the current source or voltage source that the rectifier will respond to create a relatively stable current or voltage.

2.2.Filter

The filter is responsible for flattening the output voltage after each rectification.

2.3.Insulated Gate Bipolar Transistor

The main function of IGBT is to convert direct current into alternating current with variable frequency and work with independent load.

IGBT can be one of three types:

#Voltage Source IGBT: This is a type of inverter that outputs the output voltage to the load, which is pre-defined in terms of current depending on the load properties. The supply voltage source needs to be an electromotive force source with a small internal resistance.

In motor control applications and commonly used voltage source inverters.

# IGBT line source: the current source inverter is the opposite of the above voltage source inverter. The load output current pattern is predefined, while the voltage pattern is load dependent.

The power supply must also be a current source to ensure a steady DC current.

Therefore, if the source is electromotive force, it must have a large enough input inductance or ensure the above conditions according to the principle of stable current control.

#resonant IGBT: this is the type that uses the principle of resonance when the circuit works, so the bonus voltage has a sinusoidal shape, both the voltage and the current we load depend on the load properties.

3.Application of the inverter

Inverters are commonly used in the following devices:

# Indirect inverter for water pump: The inverter helps to control the mechanical addition, allowing optionally control the pressure and flow. The inverter helps to optimize the operation of the motors and save energy.

# Inverter for fan suction / push equipment: the inverter will help control the motor allowing to control the pressure, adjust the flow according to the necessary requirements, soft start. Helps optimize engine operation better and save more electrical energy.

# Inverter for air compressor: the normal air supply control mode is operated on / off the device, this mode will control the inlet air through the gate valve in a better way.

# Indirect inverter for conveyor: conveyor motion transmission system has a very large starting torque, the inverter will be able to generate high starting torque but still ensure the starting current within the rated range permissible limit of the power grid to operate.

Very gentle starting and stopping will be achieved by controlling the amount of time needed to speed up or slow down.

# Inverter for lifting / lowering equipment: in the lifting equipment system in construction and in industry, there are often problems with equipment in terms of technology support, in the traditional design process, it is not good enough. during operation.

Difficult to control the speed during running and can only run at a fixed low speed. The problem of increasing or decreasing the speed easily leads to mechanical shock.

Installing an indirect inverter provides braking and braking torques that make applications such as cranes and hoists possible by using an AC motor. The inverter for lifting equipment will integrate regenerative braking systems and return energy to the grid safely and economically.

Tiếng Việt

Tiếng Việt