Designed and manufactured according to European quality lines and standards, Siemens medium voltage inverters have been trusted and used by many customers. Currently, Siemens inverters are considered as the best solution for simple drive with low cost, simple operation and long life.

This article will introduce to you one of the most popular inverters among customers today, the Siemens GM150 inverter. We invite you to follow the article below.

1 – General description of the medium voltage inverter Siemens GM150

The variable speed drive of the Siemens GM150 medium voltage inverter offers simplicity in medium voltage environments. This is preceded by standardization using the SIZER technique, followed by uncomplicated integration into the system. This makes commissioning quick and user-friendly using STARTER and makes it easy for the operator to control.

And also in the process of operation, the GM150 inverter makes a difference thanks to its reliability and service friendliness.

The GM150 inverter is designed as a simple and versatile drive converter for single motor applications with variable and constant torque characteristics but no regenerative feedback.

In addition, the Siemens GM150 medium voltage inverter is optimally combined with the Siemens converter motor. In this case the sine wave filter is no longer needed resulting in a compact and efficient drive solution.

The drive converter of the GM150 inverter provides an economical drive solution that can be tailored to the customer’s needs with a wide range of optional components and accessories.

2 – Overview of the technical data of the inverter GM150

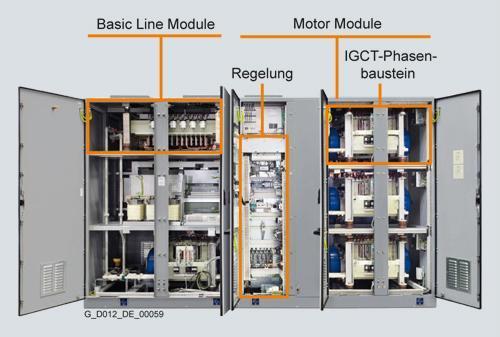

Power section with HV-IGBT technology for lifting capacity up to 13MVA

SINAMICS GM150 is the successor of SIMOVERT MV

The power part is designed with IGCT technology for capacity from 10MVA to 21MVA.

3 – Features of Siemens GM150 medium voltage inverter

3.1 – Reliability for industry

The SINAMICS GM150 inverter operates unaffected by environmental influences such as dust, corrosion and vibration. So Siemens GM150 medium voltage inverter can work well in industries such as oil and gas, water/wastewater, power generation, mining, cement, marine, metal.

The controller is insensitive to voltage fluctuations and electromagnetic interference, adding to overall reliability.

All of this is complemented by the standardization technology of SINAMICS. Siemens is the first supplier on the market to have used the reliable HV-IGBT power module in the second generation!

3.2 – Plan and operate with ease

The Siemens GM150 medium voltage inverter is mechanically integrated into the motor of the machine, so it is easier to operate

+ The front entrance allows mounting the drive cabinet on the wall

+ Simple and safe transport thanks to the integrated base frame

+ Air or water cooled

+ Compact design makes integration into existing engines easier

+ Space-saving cabinet design reduces the cost of electrical room

+ Transformer location can be freely selected: oiled transformer for outdoor installation or dry type for indoor installation.

3.3 – Personal and fast: Integrate electricity into the factory

A wide range of electrical options allows the inverter to be flexibly adapted to specific requirements:

+ Upper or lower cable input

+ All connections from the front

+ No filter is standard for new systems equipped with Siemens converter motors

+ The best prerequisites for operation with motors designed for direct online operation, using a sine wave filter

+ Current-friendly using a 12-pulse diode rectifier – or alternatively a 24-pulse diode rectifier

+ The Siemens SINAMICS GM150 medium voltage inverter (IGBT) meets Underwriter’s Laboratories requirements for the UL test mark. This greatly simplifies usage worldwide.

3.4 – Benefits of customers when using Siemens medium voltage inverter

Easy engine integration due to compact design and highly flexible configuration

Simple operator control with user-friendly control panel

Smooth and reliable operation thanks to built-in maintenance functions: automatic and good signal transducer before maintenance and/or components need to be exchanged

High durability and reliability thanks to the use of HV-IGBT technology and fuse-free design, combined with intelligent response to external disturbances

Easy integration into higher level automation systems as PROFIBUS interfaces are provided as standard analog and digital interfaces

High level of service friendliness due to innovative power section design with plug-in Powercards and excellent accessibility of all components

3.5 – Typical applications

Siemens SINAMICS GM150 medium voltage inverter is applied to the following motor systems:

+ Pumps, fans, compressors

+ Moving: Belt conveyor, train’s transmission

+ Processing: Blender, mixer, kneading machine, crusher, stirrer, rotary kiln, extruder

Tiếng Việt

Tiếng Việt