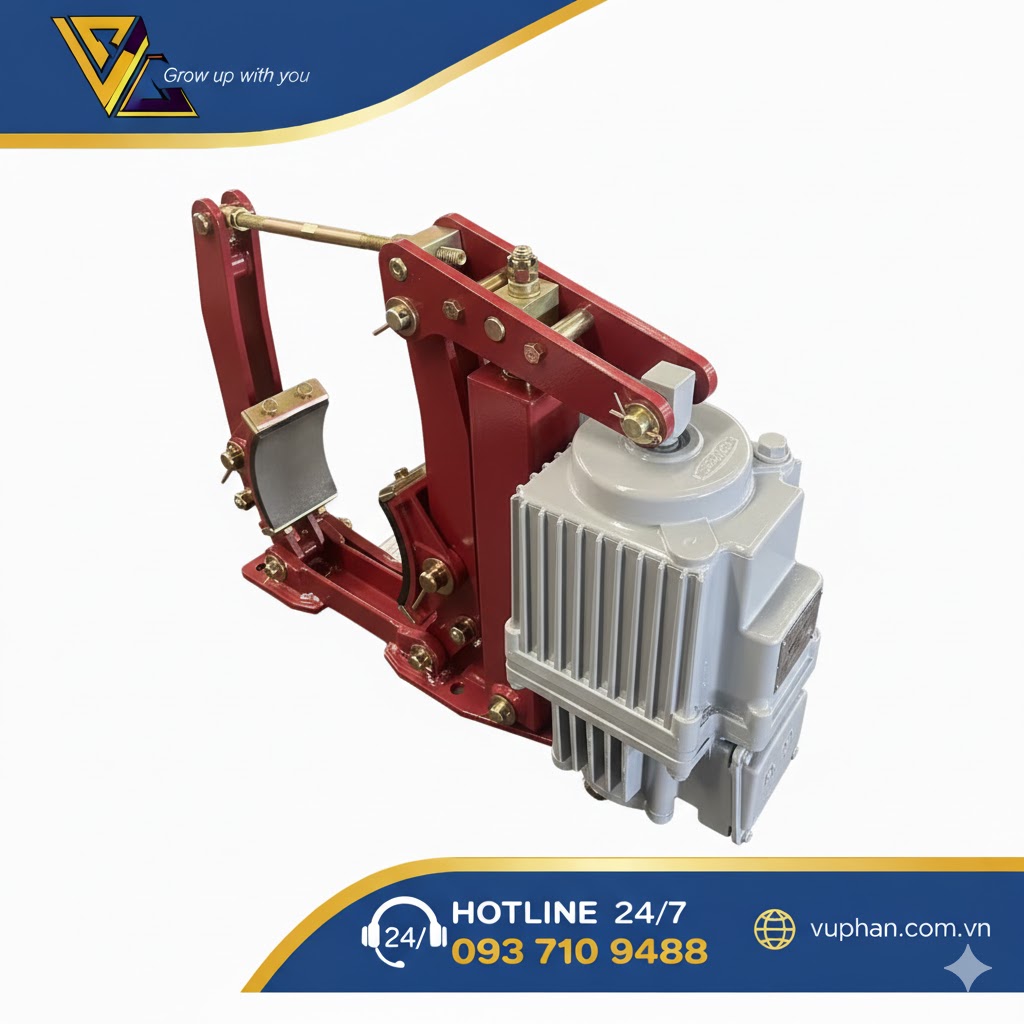

Genuine Electro-Hydraulic Drum Brake for Overhead Cranes

1. What is an Electro-Hydraulic Drum Brake?

The Electro-Hydraulic Drum Brake is a specialized safety braking device, widely used in overhead cranes, gantry cranes, conveyors, and heavy-duty industrial lifting systems.

The brake operates on a spring-applied and hydraulically released principle, controlled by an electro-hydraulic thruster. This mechanism ensures stable braking performance, fast response, and absolute safety in case of power failure (fail-safe).

It plays a critical role in load holding, motion stopping, and protecting the entire drive system in heavy industrial environments such as steel plants, ports, cement factories, and logistics centers.

1.2 Structure of the Electro-Hydraulic Drum Brake

Brake Drum

The contact surface directly engaged with the brake shoes, designed to withstand high wear and heavy loads during braking.

Brake Shoes

Made of specialized friction material to ensure stable braking force and long service life.

Brake Springs (Fail-safe)

Automatically apply the brake in case of power loss, enhancing system safety.

Electro-Hydraulic Thruster ED300-50

Provides precise brake release force, ensuring smooth and stable long-term operation.

Brake Frame & Levers

High-strength steel structure, resistant to vibration and heavy loads in harsh industrial environments.

1.2 Operating Principle

When power is supplied to the ED300-50 thruster, hydraulic force is generated to pull the lever mechanism, releasing the brake shoes from the drum, allowing the motor and transmission system to operate normally.

When power is cut off or a power failure occurs, hydraulic pressure is lost and the springs immediately press the brake shoes against the drum, stopping system movement. This fail-safe mechanism ensures maximum safety for both personnel and equipment.

2. What models are available for YWZd Electro-Hydraulic Drum Brakes?

| Brake type | Thruster type | Brake torque (Nm) | DIMENSION | Weight (kg) | |||||||||||||||||

| D | h1 | k | i | d | n | b | F | G | J | E | H | A | Q | L | C | ||||||

| A | B | A | B | ||||||||||||||||||

| Drum Brakes YWZB-200/30 | YTD300-50 | 100–200 | 200 | 170 | 175 | 60 | 17 | 8 | 90 | 100 | 210 | 245 | 200 | 475 | 425 | 390 | 80 | 120 | 260 | 80 | 33 |

|

Drum Brakes YWZB-300/30 |

YTD300-50 | 160–320 | 300 | 240 | 250 | 80 | 22 | 10 | 140 | 130 | 295 | 358 | 275 | 595 | 530 | 495 | 80 | 120 | 260 | 80 | 65 |

| Drum Brakes YWZB-300/50 | YTD500-60 | 315–630 | 585 | 525 | 97 | 157 | 340 | 97 | 86 | ||||||||||||

| Drum Brakes YWZB-400/50 | YTD500-60 | 500–1000 | 400 | 320 | 325 | 130 | 22 | 12 | 180 | 180 | 350 | 420 | 350 | 745 | 665 | 605 | 97 | 157 | 450 | 97 | 111 |

| Drum Brakes YWZB-400/80 | YTD800-60 | 800–1600 | 810 | ||||||||||||||||||

| Drum Brakes YWZB-400/125 | YTD1250-60 | 1000–2000 | 810 | 650 | 620 | 120 | 150 | 450 | 120 | 133 | |||||||||||

| Drum Brakes YWZB-500/125 | YTD1250-60 | 1250–2500 | 500 | 400 | 380 | 150 | 22 | 16 | 200 | 200 | 405 | 484 | 410 | 915 | 730 | 700 | 120 | 145 | 450 | 120 | 212 |

| Drum Brakes YWZB-600/200 | YTD2000-120 | 2500–5000 | 600 | 475 | 475 | 170 | 27 | 20 | 240 | 220 | 500 | 590 | 500 | 1075 | 840 | 810 | 120 | 150 | 450 | 120 | 309 |

| Drum Brakes YWZB-700/200 | YTD2000-120 | 4000–8000 | 700 | 550 | 540 | 200 | 34 | 25 | 280 | 270 | 575 | 760 | 550 | 1255 | 1050 | 1020 | 120 | 150 | 450 | 120 | 375 |

| Drum Brakes YWZB-800/200 | YTD2000-120 | 5000–10000 | 800 | 600 | 620 | 240 | 34 | 28 | 320 | 310 | 660 | 860 | 700 | 1480 | 1190 | 1160 | 120 | 150 | 450 | 120 | 672 |

| Drum Brakes YWZB-800/300 | YTD3000-120 | 6300-12500 | 1480 | 1085 | 1055 | 120 | 145 | 662 | |||||||||||||

3. Reputable Manufacturers of Hydraulic Drum Brakes

Well-known manufacturers of electro-hydraulic drum brakes for overhead cranes include:

– Drum brakes SIBRE (Germany) – Industrial electro-hydraulic drum brakes for heavy-duty cranes and port applications

– Drum brakes Dellner Brakes (Sweden) – High-precision electro-hydraulic drum brakes with long service life for industrial lifting systems

– Drum brakes Stromag (Germany) – Established manufacturer of drum and disc brakes for heavy industrial crane applications

– Drum brakes Emco Dynatorq (Taiwan) – Reliable electro-hydraulic braking solutions for overhead cranes

– Drum brakes HUAWU (China) – DIN/JB compliant electro-hydraulic drum brakes for cranes and conveyors

– DIN & JIS compliant OEM manufacturers – Industrial drum brakes widely used in steel plants, cement factories, and logistics facilities

4. Why Choose Electro-Hydraulic Drum Brakes from Vu Phan?

Vu Phan is a professional supplier of crane braking systems and industrial power transmission components in Vietnam, with extensive hands-on experience in heavy-duty crane projects.

Vu Phan’s commitments:

– Supplying genuine electro-hydraulic drum brakes with correct models and technical specifications

– Professional consultation to select the most suitable brake based on load capacity, speed, and actual working conditions

– Technical drawings, installation guidance, and operation support

– Stable performance, high safety level, and long service life

– Competitive pricing with transparent and reliable sourcing

Choosing electro-hydraulic drum brakes from Vu Phan ensures safe operation, minimizes failure risks, and optimizes long-term maintenance costs for crane systems.

English

English

Đánh giá

Chưa có đánh giá nào.