What does the inverter do? Inverter is a device used to change the frequency of alternating current from one frequency to another and can be adjusted. You will hear about the inverter a lot in the production activities of the automation industry, so what is its effect, we invite you to join us to find out in this article.

If you do not know what an inverter is, please see the article below.

View details >> What is an inverter? Share information about Inverters

1.What effect inverter

1.1.Helps protect the engine

The inverter can change the speed of the motor easily, so the starting current of the motors will not be able to exceed 1.5 times of the traditional starting current. Inverters often have an internal electronic system to help protect against overcurrent, high voltage and low voltage conditions, helping to create a safe system during operation.

1.2.Helps reduce mechanical wear

During the start-up process, the inverter will help the motor’s speed to be started from a steady low, not start suddenly, this will help the motor carry a large load to avoid mechanical damage. and bearing, which increases the life of the motor.

1.3.Help save electricity

Compared with the traditional starting system, the inverter will help save electricity up to 20-30%.

Since the inverter can be easily changed in speed, saving energy for the loads will not need to run at its full capacity.

1.4.Helps improve productivity and product quality

Thanks to the inverter, the motors can run faster, usually from 54-60Hz and normally 1500v/p with 50Hz.

When there is an inverter, 1800v/p with 60Hz will help increase the output for the machines to help increase the speed of the motor’s ventilation fans.

1.5.Help improve technology

Thanks to the working principle of reverse-conversion through “diode” and “capacitor”, the “cosphi” coefficients are at least from 0.96. The reactive power from the motor is very low, almost ignored, so it will reduce the current significantly during operation, reduce the line shortage, and reduce the installation cost of the capacitor bank.

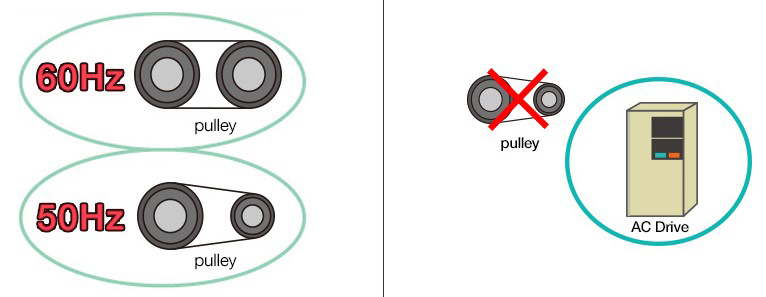

2.What are the benefits of inverters in production?

2.1.Helps protect the engine from mechanical wear

During the process of starting the engine directly from the grid, the problems of shock and mechanical wear are out of control.

Thanks to the inverter, the motor will be quieter, even if the process of starting or stopping the engine occurs continuously. In addition, the inverter also helps to minimize mechanical wear.

2.2.Help save electricity and protect electrical equipment in the same system

When the motor starts directly, the starting current is many times larger than the rated current, causing the power consumption to increase.

The inverter provides quieter starting and lower starting current than rated current.

At the same time, it will not cause voltage drop for other electrical equipment in the same system.

For pump loads, fans, air compressors, etc. need to control flow/pressure, the inverter will help stop the motor at no-load, thereby saving maximum electrical energy.

2.3.Helps increase production productivity

If we apply inverters to industries such as textiles, dyeing and plastics, etc., the inverter will help increase work productivity much more than when using direct power, eliminating accessories. accompanied by bulky but inefficient as pulley, auxiliary motor, …

2.4.Help meet technology requirements

When applying inverters to paper, printing, steel, water pressure, pneumatics, cranes, elevators, etc., it will help improve productivity and meet technological requirements.

3.Advantages of inverter

1-The speed of motor can be changed freely.

2-when starting and when stopping smoothly.

3-No need to change pulley.

4- can help reduce the capacity of the power supply.

5-way rotation can also easily be changed.

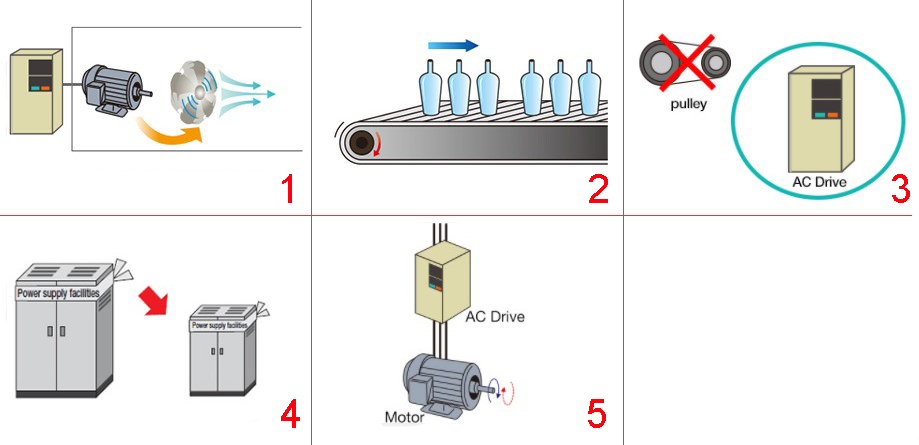

#What effect does the inverter have on the fan pump?

Without using an inverter: you will not be able to change the speed of the motor and in addition, you will need to adjust the air flow by using a damper or valve. on-off. Even if you reduce the airflow, the amount of electricity used will not change significantly.

Using inverter: the speed of motor will be changed freely, for fan and water pump. This helps to save a lot of electricity.

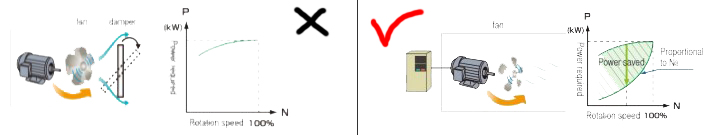

# What effect does the inverter have on the conveyor?

Do not use the inverter: during the start of the conveyor belt, there may be a sudden stop, causing the objects on the conveyor to fall or fall out.

Using the inverter: during starting or stopping with the load, it will work “slowly” slowly or smoothly, so that the items on the conveyor do not fall.

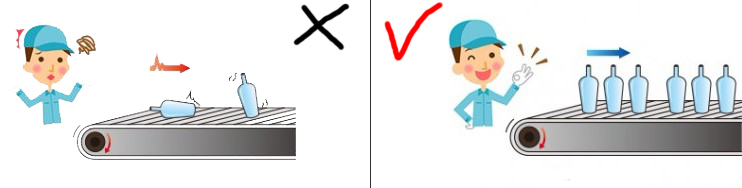

# What effect does the inverter have on the frequency-changing power grid?

Do not use an inverter: you will not be able to change the speed of the motor and must adjust the speed using a pulley. It takes a force to move and is time consuming, unscientific.

Using an inverter: thanks to the inverter, it will help standardize machines used for both 50Hz and 60Hz power sources.

Tiếng Việt

Tiếng Việt