What is an inverter used for? In the field of industrial production, it is impossible not to mention inverters. This is a device used to change the frequency of the current applied to the coil inside the motor, thereby changing and controlling the speed of the motor to help operate more efficiently.

1.What is an inverter used for?

Inverter is a commonly used device for applications in many fields with many different purposes. The most common is the application of the inverter in the uninterruptible power supply system, also known as the UPS.

The main purpose is to provide power to maintain equipment operating throughout the production process without interruption when there is a power failure.

2.Working principle of inverter

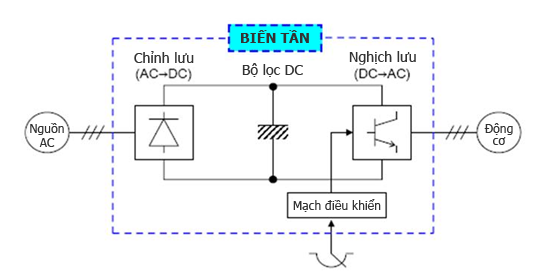

The inside of the inverter is the part that recognizes the fixed-frequency input voltage to convert it into a variable-frequency voltage to control the motor’s speed.

The internal components of the inverter include: rectifier, filter, inverter, control circuit, AC reactor, DC reactance unit, braking resistor, keyboard, display. display (monitor),…

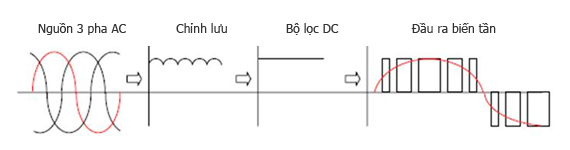

First, a single or three-phase power source is rectified and filtered into a flat DC source, which is performed by a diode bridge rectifier and a capacitor.

Power input can be single phase or 3 phase, however it will be at fixed voltage and frequency.

The DC voltage above will convert, also known as the invert, into a symmetrical 3-phase AC voltage. Initially, the generated DC voltage will be stored in the capacitor array.

Then, through proper self-activation, the IGBT converter will generate a 3-phase AC voltage by PWM pulse width modulation.

3.Benefits of using an inverter

The benefits of using an inverter must follow as follows:

The inverter makes it easy to change the speed of the motor and reverse the rotation of the motor.

The inverter helps to reduce the motor starting current compared to the direct starting method, so it will not cause a voltage drop or difficult to start.

The inverter has the ability to help start the motor from low speed so that the motors carrying large loads will not have to start suddenly. This will avoid damage to mechanical parts, bearings and help prolong the life of the engine.

The inverter provides significant energy savings compared to the direct motor starting method.

The inverter creates a safe system when operating the motor due to its electronic protection system for overcurrent, overvoltage and undervoltage.

Tiếng Việt

Tiếng Việt