Medium voltage inverter is one of the most commonly used inverters today. For units using machinery with medium-voltage motors with a voltage range from 1kV to 66kV, a medium-voltage inverter must be used. So what is a medium voltage inverter? And the working principle of medium voltage inverter like? Today’s article will share with you the most detailed information, please refer to it.

1 – What is a medium voltage inverter?

First, we need to understand what is an inverter concept? Inverter also known as Inverter, this is an electronic device that converts DC current into AC and vice versa with different frequency and phase configuration.

Depending on the application of the inverter, there will be types of inverters such as: AC inverter, DC inverter, 1-phase inverter, 3-phase inverter, motor speed control inverter, grid-tied inverter, elevator inverter, low voltage inverter, medium voltage inverter.

So what is a medium voltage inverter? In general, medium voltage inverters, like other types of inverters, are just devices that change the motor speed by changing the frequency of the current. However, medium voltage inverters are used for motors with voltage ranges from 1kV to 66kV.

2 – How many types of medium voltage inverters are there?

Depending on the installation space and capacity of the medium voltage inverter, it can be classified into the following types:

Compact: specialized for small areas, this is a compact inverter.

Separated: this is a moderate capacity inverter, so the size is not too large, just right. This inverter can cool well.

Water cooled: this is a series of inverters for currents greater than 800A, so it needs to be cooled by water to ensure equipment life and productivity.

Thus, you have turned what are the types of medium voltage inverters, so depending on the purpose of use, you can choose the type of inverter accordingly.

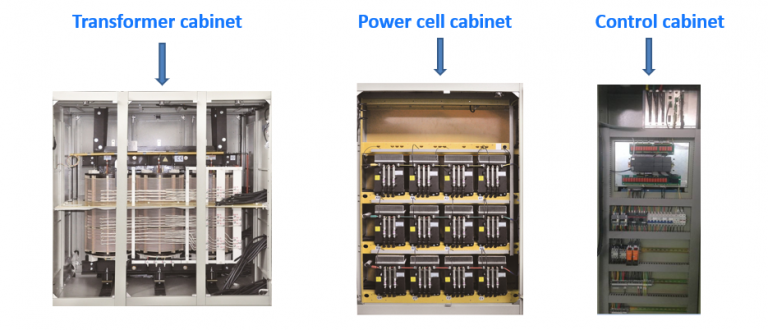

3 – How is the medium voltage inverter constructed?

With each type of capacity and use demand, the medium voltage inverter will have different structure, but still have the following main components:

Control cabinet: includes PLC and communication module, has the function of calculating and sending signals to power cells.

Transformer cabinet: has the function of lowering the source voltage to the appropriate level and supplying power cells.

Power cell: depending on capacity and voltage, each phase can have from 3 to 8 power cells or more.

The cooling cabinet for the inverter type must be cooled by water: including the pump, the compressor and the components needed to generate cooling water for the inverter.

Thus, you already know what the structure of a medium voltage inverter is, depending on the function used, the structure of the inverter may be different.

4 – How does a medium voltage inverter work?

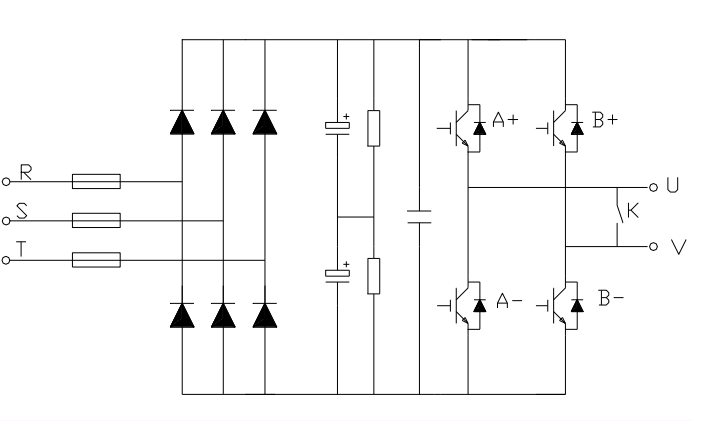

In the medium-voltage inverter, there will be power cells that act as small inverters, with the function of rectifying the low-voltage alternating current into alternating current with the required frequency.

The power cells are controlled by optical signals, which ensures synchronization. Power cells are connected in series or cascaded together, thereby generating the required output voltage.

With the above sharing, you were able to understand the basic concepts of what a medium voltage inverter is, its structure and operating principle. One thing to note is that the investment cost for medium voltage inverters is relatively large, so choosing a good quality inverter with a suitable cost is very important.

VPIC believes that it is always a reputable inverter supplier and consultant in Vietnam. Here, we always provide genuine products at competitive prices, besides, customer service is always our top priority. So we are always ready to support customers 24/7 on technical.

For more detailed advice, you can contact Hotline 0896 422 224

Tiếng Việt

Tiếng Việt