With the development of machinery equipment, production lines, and equipment in daily life, there are inevitable disadvantages. The inverter was born to overcome the disadvantages and help increase productivity and operate more efficiently. Not only that, the inverter also helps to prolong the life of the equipment. This article will learn about inverters in more detail, please follow along.

1.Learn about inverters

1.1.What is an inverter concept?

An inverter is a device capable of changing the frequency of the current applied to the coil inside the motor and through that it is possible to control the speed of the motor stepless without the use of electrical components. mechanical gearbox.

The inverter is a device that converts alternating current at one frequency into alternating current at another frequency that can be adjusted.

Normally, the inverter will use semiconductor components to be able to sequentially close / disconnect the motor windings to generate a rotating magnetic field that rotates the rotor.

The inverter can also vary from 1Hz-50Hz or up to 60Hz-400Hz for high-speed motors in CNC machines.

Thanks to the inverter, the motors will work faster than usual compared to running at 50Hz.

1.2.Inverter classification

Inverters are divided into 2 types, AC and DC.

AC inverter is widely used, AC inverter is designed to control the speed of AC motor.

DC inverter is a type of inverter that helps control the branching of a DC motor.

1.3.Structure and working principle

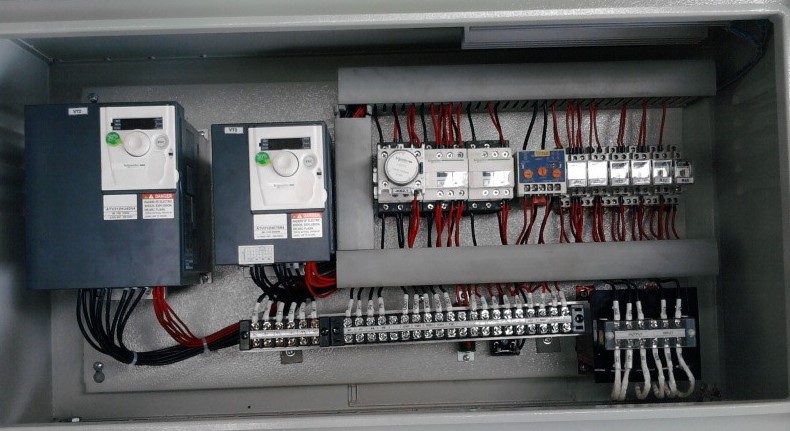

The structure of the inverter is the functional parts that can receive power with a fixed input voltage with a fixed frequency. From there, it transforms into a three-phase variable voltage and frequency power source that controls the motor’s speed.

The main parts of the inverter are: control part, DC link intermediate DC circuit, rectifier circuit, inverter circuit…

# rectifier: This is the first part in the process of turning input voltage -> desired output voltage for the motor during rectification. This is achieved by using a full wave diode bridge rectifier.

#dc line: this is a capacitor bank that stores rectified DC voltage. A capacitor can store a large charge, but arranging them in a d.c. route configuration increases the capacitance.

#IGBT: this is a recognized device for high performance and fast switching. Internally the inverter will be switched on/off in sequence, which can generate pulses of different widths from the DC feeder voltage stored in the capacitors.

#AC Reactor: this is an inductor or coil AC reactor. The inductor will store energy in the magnetic fields generated in the coil and resist changes in the current.

#D.c. reactor: has the function of limiting the instantaneous current change rate on the d.c. line. This variable speed reduction will allow the actuator to detect potential problems before failure and trip the actuator.

#brake resistor: the excess power generated needs to be dealt with somehow. Resistors will be used to quickly burn off this excess electricity generated by turning excess electricity into heat.

The working principle of the inverter is:

The 1-phase/3-phase power supply is first rectified and filtered into a flat DC power source. This stage will be performed by diode bridge rectifier and capacitor.

The input power will probably be single phase or will be three phase but it will be at a fixed voltage and frequency.

The DC voltage at the top will be converted inversely into a symmetrical three-phase AC voltage.

Initially, DC voltage will be generated and stored inside the capacitor array. then through proper trigger sequence processing the IGBT converter will generate a three-phase AC voltage by PWM pulse width modulation.

1.4. Learn about the advantages and disadvantages of inverters

#Advantages

Capable of changing the frequency of the current and changing the rotational speed of the motor flexibly effectively.

Helps the engine save maximum energy.

Helps the engine to operate stably with less damage.

Repair/maintenance costs are not too high.

Helps increase engine life.

Helps increase engine performance in production and business.

Can work in many different environments.

Meet many different applications.

Good support for equipment that needs to change the speed of many motors at the same time such as conveyors or looms, etc.

It has a full range of dynamic protection functions such as overcurrent, overvoltage, phase loss or phase reversal, etc.

With the central control system, it is possible to connect to the network.

It is possible to adjust the frequency according to the desired speed setting value.

Makes it easy to connect to automatic control systems.

#Defect

To be able to use and operate effectively, it is necessary to have knowledge of inverters.

High initial investment cost.

Starting or stopping the asynchronous electric motor with medium or large capacity, it is often necessary to use the direct starting method, so it is easy to cause voltage drop on the line.

The rotational speed of the induction motor can only be controlled step by step, normally each motor can only change one of the synchronous speed ranges.

During use, regular maintenance is required.

2.Benefits of using an inverter

It is easy to reverse the direction of rotation of the motor or change the speed of the motor.

No pressure drop or hard to start.

Starting slowly or steadily from low speed helps to prevent large-loaded motors from starting suddenly, helping to avoid mechanical damage.

Compared with the direct motor running method, the inverter helps to save energy to the maximum.

Integrated in traditional modules will make it easy to control and monitor through the control center.

3.Instructions for choosing an inverter

In order to be able to choose the type of inverter that suits the needs and applications, it is necessary to clearly define the application needs and the purpose of use to be able to balance the investment budget.

Here are the principles to choose the right inverter:

The inverter must be suitable for the motor type and capacity of the motor. The type of motor that needs to be installed with an inverter is what type of motor is synchronous or not, single phase or three phase, DC or AC, what is the voltage of the motor.

It is necessary to specify what the application is, how much speed is required, whether advanced control features are required, whether system synchronization is required, the working environment is humid, hot. high altitude, lots of dust, flammable, explosive, etc.

Choosing the inverter according to the load is very important, it is necessary to determine whether the load type of the motor machinery is any type of load, light load or heavy load.

Choose an inverter that is easy to set up for the operator.

If the machine already has an old inverter but wants to replace it, it is necessary to choose the correct one according to the specifications of the old inverter in use.

Hopefully with the above information, learning about your inverter will be more detailed, helping you have a better overview of the inverter.

Tiếng Việt

Tiếng Việt